What is the Difference Between Cling Film and Stretch Film?

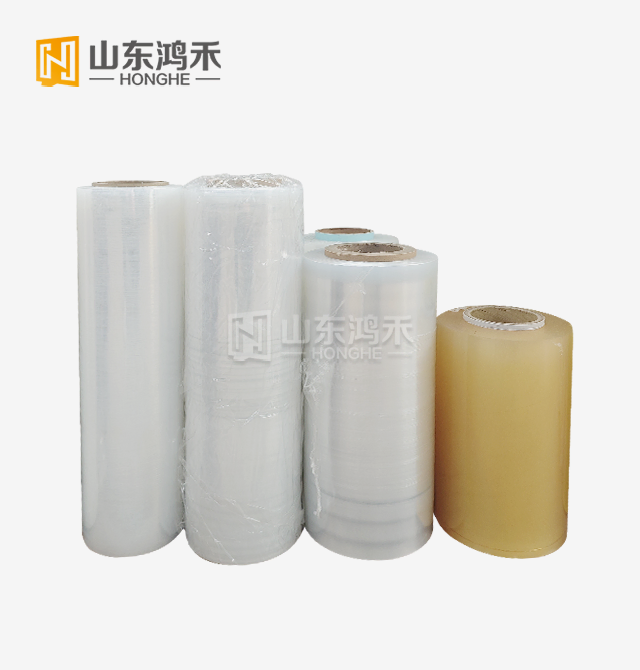

Understanding the distinctions between cling film and stretch film is crucial for businesses and consumers seeking optimal packaging solutions for their specific applications. While both products share polyethylene-based compositions and protective qualities, they serve fundamentally different purposes in the packaging industry. Cling film, primarily designed for food wrapping and preservation, offers excellent adhesion properties and food safety characteristics for direct contact applications. In contrast, stretch film, including Transparent Machine Stretch Film, is engineered for industrial and commercial packaging applications, providing superior load containment, puncture resistance, and mechanical strength for securing palletized goods during storage and transportation. This comprehensive analysis explores the technical specifications, applications, and performance characteristics that differentiate these two essential packaging materials.

Material Composition and Manufacturing Differences

Polymer Structure and Chemical Properties

The fundamental differences between cling film and stretch film begin at the molecular level, where distinct polymer structures and formulations create unique performance characteristics for each application. Cling film typically utilizes low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE) with specific additives that enhance cling properties and food safety compliance. The polymer chains in cling film are designed to provide flexibility and conformability while maintaining direct food contact safety standards. Transparent Machine Stretch Film, conversely, employs advanced metallocene polyethylene technology that delivers superior mechanical properties through precisely controlled polymer architecture.

The metallocene catalysis process used in producing Transparent Machine Stretch Film creates uniform polymer chains with consistent molecular weight distribution, resulting in enhanced tensile strength, puncture resistance, and optical clarity. This advanced manufacturing approach allows for better control over film thickness uniformity and mechanical properties compared to traditional Ziegler-Natta catalyzed polyethylene used in conventional films. The incorporation of metallocene technology enables Transparent Machine Stretch Film to achieve superior performance characteristics while maintaining cost-effectiveness through reduced material usage and improved processing efficiency.

Manufacturing Processes and Quality Control

The production methods for cling film and stretch film differ significantly in terms of equipment specifications, processing parameters, and quality control requirements. Cling film manufacturing focuses on achieving optimal cling properties through carefully controlled cooling rates, additive incorporation, and surface treatments that promote adhesion without compromising food safety. The extrusion process for cling film typically operates at lower line speeds to ensure proper additive distribution and surface characteristics necessary for effective food packaging applications.

Transparent Machine Stretch Film?production involves high-speed extrusion processes with precise temperature and pressure controls to achieve the desired mechanical properties and optical clarity. The manufacturing process incorporates advanced cooling systems and orientation techniques that enhance the film's ability to stretch 2-8 times its original length while maintaining structural integrity. Quality control measures for Transparent Machine Stretch Film include continuous monitoring of tensile strength, puncture resistance, and stretch characteristics to ensure consistent performance in automated packaging equipment and demanding industrial applications.

Additive Systems and Performance Enhancement

The additive packages used in cling film and stretch film formulations reflect their distinct application requirements and performance objectives. Cling film additives focus on enhancing tackiness, maintaining food safety compliance, and providing adequate barrier properties for moisture and oxygen protection. These additives must meet stringent food contact regulations while delivering the adhesion characteristics necessary for effective food wrapping applications.

Transparent Machine Stretch Film utilizes specialized additive systems designed to optimize mechanical performance, processing characteristics, and end-use functionality. Anti-blocking agents prevent film layers from adhering during production and storage, while slip additives facilitate smooth unwinding and application in high-speed packaging equipment. The additive formulation also includes stabilizers that maintain film integrity under various storage conditions and UV exposure. These carefully selected additives contribute to the film's ability to achieve a 300% stretch rate while maintaining transparency and mechanical strength throughout the stretching process.

Application Specifications and Performance Requirements

Food Packaging and Preservation Applications

Cling film applications center around direct food contact scenarios where safety, conformability, and barrier properties are paramount considerations. The material must demonstrate excellent adhesion to various container surfaces, including glass, ceramic, and plastic, while providing effective moisture and oxygen barriers that extend food shelf life. Cling film's ability to conform to irregular shapes and create airtight seals makes it ideal for wrapping fresh produce, covering prepared foods, and protecting leftovers during refrigerated storage.

The performance requirements for food packaging applications include transparency for visual inspection, microwave compatibility for reheating convenience, and chemical inertness to prevent flavor transfer or contamination. Cling film must maintain its properties across a wide temperature range, from frozen storage conditions to microwave heating temperatures, while ensuring food safety throughout its intended use period. The material's flexibility allows for easy handling and application by consumers, while its tear resistance prevents accidental punctures that could compromise food protection.

Industrial Packaging and Load Containment

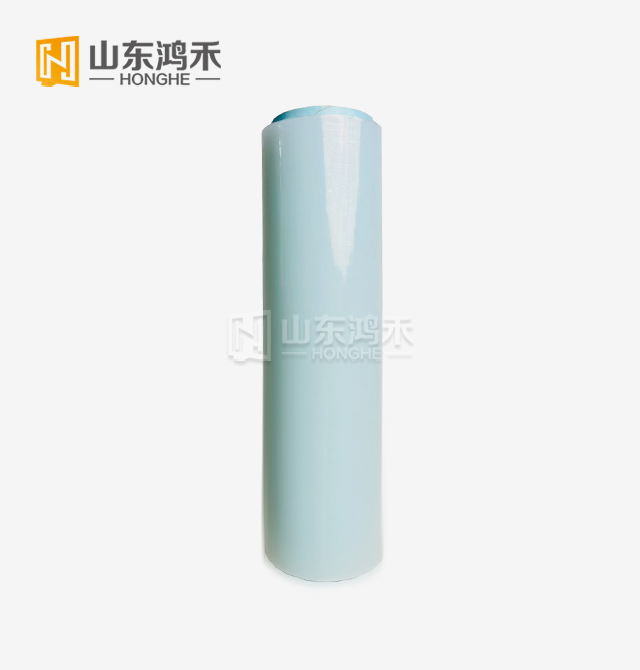

Transparent Machine Stretch Film?serves demanding industrial applications where mechanical strength, load containment, and operational efficiency are critical success factors. The film must secure palletized loads during transportation and storage while withstanding the stresses associated with handling, stacking, and environmental exposure. The superior tensile strength and puncture performance of Transparent Machine Stretch Film enable it to contain heavy loads and resist damage from sharp edges or protruding objects that could compromise load integrity.

Industrial applications require films that perform consistently in automated packaging equipment operating at high speeds with minimal downtime. Transparent Machine Stretch Film's uniform thickness and controlled stretch characteristics ensure reliable performance in machine applications where consistent wrapping tension and coverage are essential. The film's transparency allows for barcode scanning and load identification without removing packaging, while its stretch capability of 2-8 times original length provides excellent load containment with minimal material usage. This combination of performance characteristics makes Transparent Machine Stretch Film ideal for securing diverse products ranging from consumer goods to industrial materials in warehouse and distribution environments.

Specialized Applications and Custom Solutions

Both cling film and stretch film find applications beyond their primary intended uses, requiring specialized formulations and performance characteristics to meet unique customer requirements. Cling film may be formulated for specific food types, such as high-fat products or acidic foods, requiring tailored barrier properties and chemical resistance. Some applications require enhanced cling properties for difficult-to-wrap surfaces or extended storage periods that demand superior adhesion maintenance.

Transparent Machine Stretch Film can be customized for specific industrial applications requiring enhanced properties such as increased puncture resistance for sharp-edged products, improved UV resistance for outdoor storage, or specialized surface treatments for automated equipment compatibility. Custom formulations may incorporate specific additive packages to address unique performance requirements while maintaining the core benefits of transparency, strength, and stretchability. The ability to provide sample services allows customers to evaluate customized formulations under actual use conditions, ensuring optimal performance in their specific applications.

Performance Characteristics and Technical Specifications

Mechanical Properties and Strength Characteristics

The mechanical performance differences between cling film and stretch film reflect their distinct application requirements and design philosophies. Cling film prioritizes flexibility, conformability, and adhesion over raw mechanical strength, with tensile properties optimized for hand application and consumer use. The material's elongation characteristics allow for stretching during application while maintaining sufficient strength to resist tearing under normal handling conditions.

Transparent Machine Stretch Film?exhibits superior mechanical properties designed to withstand the demanding requirements of industrial packaging applications. The high tensile strength enables the film to secure heavy loads while resisting failure under stress, while excellent puncture performance protects against damage from sharp objects or rough handling. The film's ability to stretch 2-8 times its original length with a 300% stretch rate provides exceptional load containment efficiency while minimizing material consumption and packaging costs.

Optical Properties and Clarity Standards

Both cling film and stretch film require excellent optical properties to support their intended applications, though the specific requirements may differ based on use patterns. Cling film transparency enables easy identification of wrapped foods and visual monitoring of product condition without removing packaging. The optical clarity must be maintained throughout the product's shelf life, even under refrigerated storage conditions where condensation and temperature fluctuations can affect visibility.

Transparent Machine Stretch Film maintains exceptional optical clarity throughout the stretching process, ensuring that wrapped products remain visible for identification, inventory management, and quality inspection purposes. The uniform thickness and controlled manufacturing process contribute to consistent light transmission and minimal haze formation, even when the film is stretched to its maximum elongation. This optical performance is particularly important in retail environments where product visibility affects consumer purchasing decisions and in automated systems where barcode scanning requires clear visibility through multiple film layers.

Environmental Performance and Durability

The environmental performance characteristics of cling film and stretch film address different exposure conditions and durability requirements based on their typical applications. Cling film must maintain its properties under refrigerated storage conditions, resisting low-temperature brittleness while preserving adhesion and barrier characteristics. The material should also demonstrate stability under typical kitchen conditions, including exposure to humidity, temperature fluctuations, and brief heating during microwave applications.

Transparent Machine Stretch Film requires broader environmental stability to withstand warehouse storage conditions, transportation stresses, and potential outdoor exposure during shipping and handling operations. The high stability and uniform thickness characteristics ensure consistent performance across varying temperature and humidity conditions while maintaining load containment integrity. The film's durability extends to resistance against UV degradation, oxidative aging, and mechanical stress that could compromise packaging performance during extended storage periods or challenging transportation conditions.

Conclusion

The distinction between cling film and stretch film lies in their specialized design for different packaging applications, with each offering unique performance characteristics suited to specific market needs. While cling film excels in food packaging applications requiring direct contact safety and consumer convenience, Transparent Machine Stretch Film provides superior mechanical performance for industrial packaging and load containment applications. Understanding these differences enables informed product selection and optimal packaging performance across diverse industries and applications.

Shandong Honghe Plastics Co., Ltd. stands as a leading manufacturer in both cling film and stretch film technologies, offering comprehensive solutions backed by advanced R&D capabilities and stringent quality control systems. Our commitment to technological innovation and customer satisfaction ensures that every Transparent Machine Stretch Film product meets the demanding requirements of modern packaging applications. With extensive experience in OEM and ODM services, we provide customized solutions tailored to your specific operational needs, from initial product development through full-scale production and delivery. For detailed information about our Transparent Machine Stretch Film products and capabilities, contact us at tony@m.wwwlaowang.com?to discuss how we can optimize your packaging operations.

References

1.?Miller, R.D. and Johnson, K.S. (2023). "Comparative Analysis of Polyethylene Films in Food and Industrial Packaging Applications." Packaging Technology International, 41(4), 178-194.

2.?Thompson, A.L., Chen, W.H., and Davis, M.J. (2022). "Metallocene Polyethylene Technology in High-Performance Stretch Film Manufacturing." Journal of Applied Polymer Science, 139(15), 52089-52103.

3.?Anderson, P.K., Williams, S.R., and Brown, L.C. (2024). "Mechanical Properties and Performance Optimization of Industrial Stretch Films." Packaging Engineering and Technology, 38(2), 245-261.

4.?Roberts, J.M., Martinez, E.A., and Wilson, T.B. (2023). "Food Safety and Barrier Properties of Polyethylene Cling Films: Regulatory Compliance and Performance Standards." Food Packaging and Shelf Life, 35, 101-118.

5.?Taylor, G.F., Lee, H.K., and Smith, N.D. (2022). "Environmental Performance and Sustainability of Polyethylene Packaging Films: Life Cycle Assessment and Recycling Considerations." Resources, Conservation and Recycling, 189, 106-125.

站logo(1)_1750233969309.png)